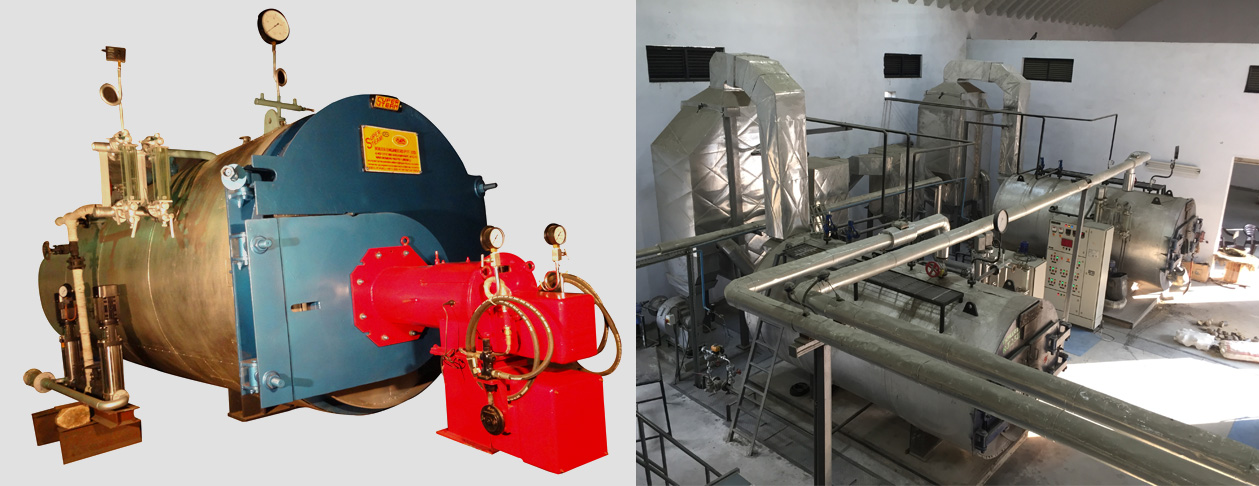

Package Boiler Manufacturers And Supplier

We are pleased to introduce as a manufacturer of various types of “SUPER STEAM” make Steam Boilers and Boiler pressure parts on turnkey basis required in various industries like Sugar Plant with Power Cogen, Petro Chemicals, Textile/Sizing Unit, Distilleries Factories, Pamseeds & Groundnut Oil Industries, Starch units, Paper Plant, Food Processing Units etc. Our range of Main Products is as mentioned below. Package Boiler Manufacturers in India.

Sugar Plant :

We undertake design, development, manufacture, supply & erection of complete sugar, jaggery, distillery plants with power co-generation on turnkey basis & boiler up to 130 TPH capacity at pressure 87 kg/cm2 with temp. 540°C.

Package boilers are compact steam generators designed for small-scale power applications, such as self-powered industrial plants. Like other boilers, they produce steam for various purposes. However, these boilers are specifically built to generate a smaller volume of steam due to their compact size. While their structure may appear complex, the advantage lies in their pre-assembled design, as they are fully packaged in the factory. This eliminates the need for on-site assembly, ensuring easy and efficient installation.

An Engineered System to Reduce NOx Emissions :

The I-SCR System was designed by Indeck to help reduce the emissions of nitrous oxide (NOx) on industrial boiler systems. This system uses a selective catalytic reduction process that converts nitrous oxide emissions in the combustion flue into harmless nitrogen (N2) and water (H20) without forming secondary pollutants.

Burner Management and Combustion Controls :

Nearly half a century of field experience in packaged industrial boiler systems has led to the development of our burner management and combustion control systems. Our in-house engineering, UL listed panel shop, and large component inventory allow us to develop custom systems very quickly.

We provide emergency water treatment trailers for many purposes including use with rented boiler systems, in-plant deaerator inspections, and equipment expansion or replacement. Our trailer-mounted deaerators will meet your flow rate and water quality requirements to keep the plant on-line.

We understand the importance of properly integrated accessories to complete industrial steam boiler systems. Our engineering staff ensures that the required interface is in place so that the overall boiler system performs at optimum efficiency.

Boiler Parts :

At Indeck, our top priority is to keep our customers up and running at maximum efficiency. We have over $25 million worth of boiler parts in stock to help reduce downtime as well as improve and maintain the efficiency of your boiler system and accessories.

We are pleased to introduce as a manufacturer of various types of “SUPER STEAM” make Steam Boilers and Boiler pressure parts on turnkey basis required in various industries like Sugar Plant with Power Cogen, Petro Chemicals, Textile/Sizing Unit, Distilleries Factories, Pamseeds & Groundnut Oil Industries, Starch units, Paper Plant, Food Processing Units etc. Our range of Main Products is as mentioned below.

Sugar Plant :

We undertake design, development, manufacture, supply & erection of complete sugar, jaggery, distillery plants with power co-generation on turnkey basis & boiler up to 130 TPH capacity at pressure 87 kg/cm2 with temp.

Combi Boiler :

We are pleased to introduce as a manufacturer of various types of “SUPER STEAM” make Steam Boilers and Boiler pressure parts on turnkey basis required in various industries like Sugar Plant with Power Cogen, Petro Chemicals, Textile/Sizing Unit, Distilleries Factories, Pamseeds & Groundnut Oil Industries, Starch units, Paper Plant, Food Processing Units etc. Our range of Main Products is as mentioned below.

Sugar Plant :

We undertake design, development, manufacture, supply & erection of complete sugar, jaggery, distillery plants with power co-generation on turnkey basis & boiler up to 130 TPH capacity at pressure 87 kg/cm2 with temp. 540°C.